Hydroxypropyl Methyl Cellulose is a versatile, water-soluble, and non-ionic polymer, sourced from wood or cotton linter and obtained through etherification. LANDU LANDERCOLL HPMC is widely used as a water retention agent and thickener in the dry-mix mortar system.

Owning three dedicated laboratories, LANDU offers tailored HPMC solutions for applications and rigorous test reports based on your requirements.

Certified by the global stringent EU REACH and ISO standards, LANDU HPMC proves to be safe and high-quality and will be continuously improved.

LANDU ensures the best and consistent HPMC products by setting high standards for raw materials and the production process in our own factories.

Besides helping you find the best HPMC products and solutions, we can also offer fine-tailored videos to show HPMC performance or give guidance.

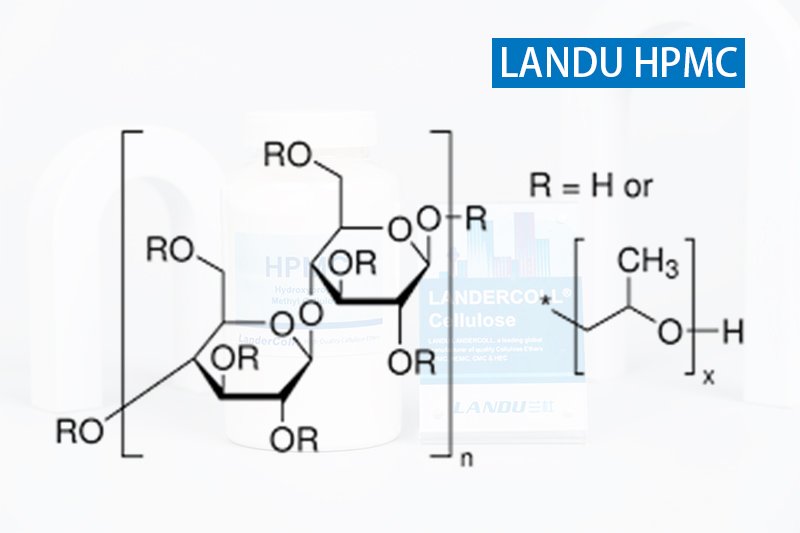

HPMC, short for Hydroxypropyl Methylcellulose, is a non-ionic cellulose ether derived from the chemical modification of natural cellulose (e.g., wood pulp or cotton fibers). Based on Methylcellulose (MC), HPMC is further modified by introducing hydroxypropyl (-OCH₂CHOHCH₃) groups, combining the properties of methyl and hydroxypropyl substituents. This enhances its solubility, gelation temperature, and stability.

As an influential manufacturer of HPMC, LANDU provides various grades of HPMC as a powerful thickener, binder, film former, and stabilizer. Our superior products are widely used in detergent and dry-mix mortar, such as tile adhesive, wall putty, self-leveling compounds, EIFS systems, etc.

| Product Name | Hydroxypropyl Methylcellulose | NDJ Viscosity Range | 300 -215,000 |

|

Moisture Content

|

≤6%

|

Particle Size | 98% pass 80 mesh |

|

Ash Content

|

≤5%

|

pH Value | 6-8 |

Try before you decide! LANDU, a leading Chinese HPMC manufacturer, supplies free samples (200g–600g) for testing. We provide free global shipping for all samples. Should the samples fail to meet your expectations, simply share your feedback, and our R&D team will refine and optimize the formula to deliver your ideal performance.

Among the range of economical-grade HPMC, LANDU provides high-viscosity HPMC, which is ideal for C0 and C1-grade tile adhesive as well as the EIFS system, etc. This series focuses on saving your costs while delivering good water retention and thickening performance

LANDU Standard-grade HPMC is suitable for most applications, such as C1 and C2 tile adhesive and wall putty(also called skim coat). Such HPMC performs great in retaining water, enhancing open time, and improving workability.

LANDU also provides highly modified, low-viscosity HPMC for demanding projects in the European market, such as C2TE tile adhesive(S1/S2). LANDERCOLL Premium HPMC shows high water retention, enhanced open time, excellent workability, and improved slip resistance.

You can choose from T/T, L/C, OA, and more methods while paying for orders.

Quality is the top priority in the LANDU HPMC manufacturing process.

LANDU’s fast and trackable logistics service is here to reassure you.

Contact LANDU for Reasonable MOQs, tailored formulation, and free consultations.

HPMC significantly delays water evaporation, improving workability and hardening effects.

LANDERCOLL HPMC extends product lifespan through stronger bonds.

HPMC is non-toxic, biodegradable, and free from persistent pollution.

LANDU, a leading cellulose ether manufacturer partnering with global industry leaders, dedicates itself to excellence in quality, in-house innovation, and cutting-edge R&D.

We are certified by ISO 9001 and EU REACH certification, with 11 patents and 4 utility patents. LANDU owns an independent R&D Center that does the physical and chemical tests for every batch of raw materials and finished products to ensure the stable and consistent quality of our products.

In addition to adopting premium raw materials, LANDU employs a range of advanced production equipment and systems to ensure highly efficient productivity and a safe, reliable manufacturing environment. With three major production bases and an annual capacity of 75,000 tons, along with large-scale warehousing capabilities, we guarantee to meet your production demands.

Our client-centric approach includes tailored product formulation—LANDU adjusts key specifications (viscosity, solubility, open time, etc.) to meet exact application requirements. To facilitate evaluation, we also provide complimentary product samples accompanied by detailed testing protocols and application guidelines, ensuring reliable performance validation.

HPMC acts as a water-retainer, thickener, and bonding enhancer in tile adhesives, ensuring workability and adhesive strength.

HPMC provides water retention, thickening, and smooth workability, preventing cracking and enhancing adhesion.

At LANDU, we understand that every customer has unique requirements for packaging size, material, and handling. That’s why we offer flexible packaging options for our high-quality HPMC, ensuring optimal convenience, protection, and cost-efficiency for your operations.

While HPMC alone delivers excellent performance, pairing it with specialized additives can further optimize Workability & Rheology, Setting Time & Durability, Water Retention & Adhesion, Mechanical Strength & Stability.

Redispersible Latex Powder

Polycarboxylate Superplasticizer

If you need further clarification or have a specific technical requirement, we’re just a message or call away! We’re committed to helping you find the perfect fit for your needs. Let’s collaborate—contact us today!

Pre-dispersion method: First, mix HPMC with a small amount of other powder (e.g., cement), then add water and stir.

Adjust water temperature: Disperse in cold water first, then heat to 60°C for dissolution (avoid direct hot water addition).

Extend stirring time: Use a high-shear mixer to accelerate dissolution. Tip: Choose surface-treated HPMC (e.g., instant-dissolving grade) to reduce the risk of lump formation.