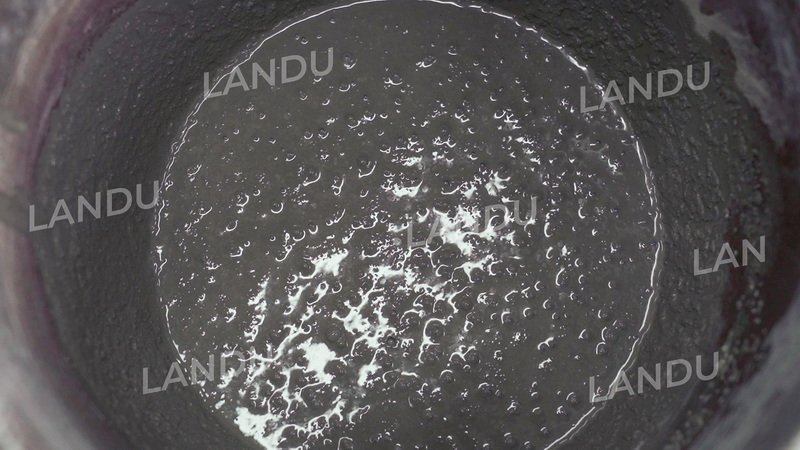

In the world of construction chemicals, foam control may seem like a small detail, but it has a big impact. Whether in cementitious mortars, gypsum compounds, self-leveling underlayments, or architectural coatings, excess foam can reduce density, weaken mechanical strength, and create visible surface defects. That’s why choosing the right building-grade defoamer is essential for manufacturers, formulators, and contractors who want consistent performance and defect-free finishes.

This article compares the top global defoamer manufacturers in 2025, highlighting their chemistry focus, applications, and key advantages, so you can make an informed sourcing decision.

Building-grade defoamers are specialty additives designed to prevent or eliminate foam during mixing, pumping, or application of building materials. They can be supplied as liquids, emulsions, or powders, depending on the system.

In cementitious systems (tile adhesives, grouts, mortars, self-leveling compounds): Silicone or powder defoamers perform best due to high alkalinity.

In gypsum-based compounds (joint fillers, putties, plasters): Oil- or silicone-based emulsions are widely used.

In coatings and paints: Gloss-safe silicone or polyether blends prevent microfoam and pinholes without surface defects.

In concrete admixtures: Specialty antifoaming admixtures improve density, flow, and compressive strength.

Here’s a comparison of the leading players shaping the defoamer market in 2025:

| Manufacturer | Key Brands/Series | Chemistry Focus | Building Segments | Key Strengths |

|---|---|---|---|---|

| BASF | FOAMSTAR, FOAMASTER | Silicone & non-silicone | Coatings, compounds | Low-VOC, broad resin compatibility, strong foam control |

| Dow | DOWSIL, XIAMETER | Silicone emulsions & compounds | Cementitious, paints, sealants | Fast knockdown, alkaline persistence |

| Evonik | TEGO Foamex | Siloxane & polyether blends | Coatings, adhesives | Gloss-safe, microfoam control |

| BYK (ALTANA) | BYK Defoamers | Silicone & non-silicone | Coatings, flooring, composites | High-gloss defect control, grind/letdown pairing |

| Wacker | SILFOAM | PDMS silicone antifoams | Mortars, gypsum, dispersions | Alkaline stability, low dosage efficiency |

| Elementis | DAPRO | Mineral oil, silicone, polyether | Coatings, compounds, putties | Balanced foam control at different PVC |

| MÜNZING | AGITAN, DEE FO | Polyether, silicone, mineral oil, powders | Coatings, drymix mortars, adhesives | Dry-blend powder defoamers, strong deaeration |

| Sika | Sika Defoamers | Defoaming admixtures | Concrete, mortars | Application know-how, dosing guidance |

| Elkem Silicones | SILCOLAPSE | Silicone antifoams | Cementitious processes, water | Process stability under shear |

| Shandong Landu | LANDU NOVASTAR | Powder & liquid defoamers | Tile adhesives, skim coats, SLUs, coatings | Easy dry blending, pinhole reduction, low moisture uptake |

When selecting a construction defoamer, match the chemistry to your system:

Cementitious / high-pH mortars → Silicone-based or powder defoamers.

Gypsum systems & joint compounds → Oil/silicone emulsions.

High-gloss coatings → Gloss-safe silicone or polyether blends.

Adhesives & sealants → Low-migration, residue-free defoamers.

💡 Pro Tip: Always start with the lowest recommended dosage and ladder up, validating both fresh mix properties (density, flow, viscosity) and final performance (strength, adhesion, surface finish).

As construction shifts toward sustainability, low-VOC formulations, and defect-free surfaces, the role of defoamers becomes more critical. The right supplier not only provides additives but also technical expertise, application testing, and global logistics support.